In this article, we’ll advise what to look for in a wood lathe and review four products to compare quality, specification, price, and capability. Ranging from budget lathes to more serious offerings, benchtop machines, to pedestal supports, I’ll provide you with the information you need to support an informed buying choice.

Here’s a list of the lathes we’ll be reviewing:

- Shop Fox W1704 1/3-Horsepower Benchtop Lathe

- Rikon Power Tools 70-105 10″ x 18″ 1/2 hp Benchtop Mini Lathe

- Grizzly Industrial T25920-12″ x 18″ Variable-Speed Benchtop Wood Lathe

- Grizzly Industrial G0766-22″ x 42″ Variable-Speed Freestanding Wood Lathe

Lathe Components

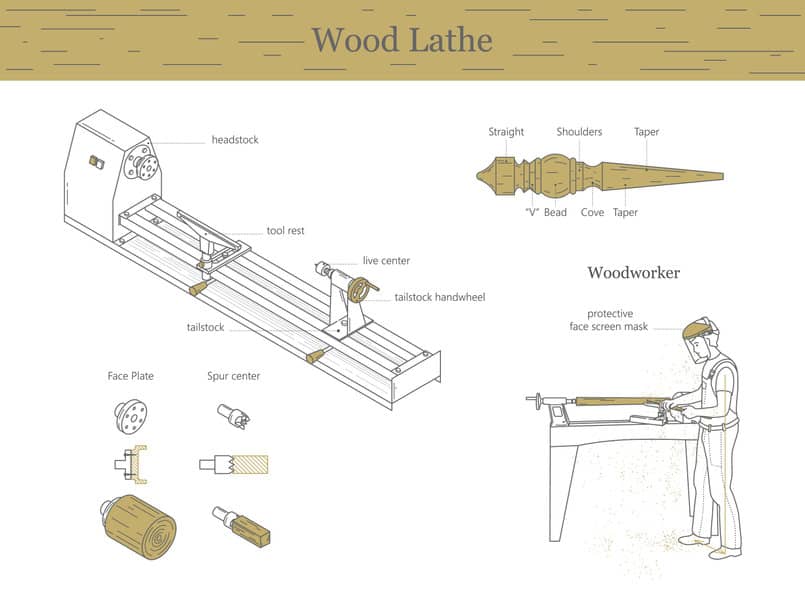

Before we get into the details of these specific products, let’s understand what a wood lathe is and the main components for those new to woodturning.

Wood lathes are quite simple machines. They consist of a motor driving a spindle, normally through a drive belt. That spindle is in a part of the lathe called a headstock. The headstock sits on a bed, at the other end of which sits another spindle, called the tailstock. The tailstock is movable and can slide along the bed toward or away from the tailstock. Between the headstock and tailstock, you place the timber you wish to turn.

On the bed, there is an adjustable device called a tool rest. The tool rest is the support against which you rest your chisels or tools when turning.

Features

When buying a wood lathe, here are some things to consider:

Benchtop or freestanding?

While the terms are self-explanatory, you need to analyze which suits your needs and your workshop space. The benchtop units are generally smaller and allow you to bolt them to a workbench of your choosing. The freestanding units will have legs or an enclosed base to allow you storage. Regardless of your choice, the important consideration is how heavy and solid the lathe is.

Vibration is undesirable in a wood lathe, and when you start turning a piece of wood, it can be unbalanced until you’ve roughed the surface down. Quality lathes are made of cast iron for weight and strength. Some lightweight lathes made of angle-iron or sheet metal are not a great choice unless you can add weight or bolt them to a solid bench.

Motor power

The horsepower of the motor on a wood lathe dictates the size of the wood you can comfortably turn. The lathes we review here today range from 1/3rd horsepower through to 3 horsepower, and more expensive lathes can have motors rated higher. Horsepower adds cost, but it also gives greater capability.

If you want to turn small spindles such as pen blanks, the lower range will suit you fine. However, if you intend to swing large bowls or logs, then you’ll need to ensure the lathe has the power to cope.

Swing over the bed

This measurement dictates the largest diameter piece of wood you can physically turn on the lathe. The measurement is from the center of the headstock spindle to the lathe’s bed.

Distance between centers

This distance tells you the maximum length of timber you can turn. It measures the distance between the headstock spindle and the tailstock spindle, with the tailstock as far toward the end of the bed it can go and the spindle quill retracted into the tailstock as far as possible.

Morse taper size

The accessories that you put into the headstock spindle or tailstock quill have a shaft that is tapered and that taper matches the internal taper of the spindle or quill. This taper ensures a good friction fit while working but allows you to knock them out when finished.

You will come across three standard tapers, numbered #1, #2, and #3. There are larger morse taper sizes, but they’re used for heavy industrial work, so you’re unlikely to encounter them. A #2 morse taper is pretty standard for the types of lathes we will be reviewing.

Spindle bore size

When you come to knock out the morse taper accessory fitted to the headstock, you do this with a bar that goes through the middle of the spindle bore. Knowing this size lets you choose the right size knockout bar.

Spindle thread

As well as having a tapered bore, the headstock spindle has an external thread, which is used to screw on chucks and faceplates. You’ll need to know this measurement to buy the right accessories.

Speed control

You will need your lathe to have some form of speed control to ensure the correct cutting speed is maintained, regardless of the diameter turned. This control can take several forms; it can be manual by changing a belt on stepped pulleys, it can be electronic, using a rheostat, much like a light dimmer, or it can have gears.

Is it reversible?

The reverse function on a lathe comes in handy when you’re finishing your piece and wish to sand it. While not essential, it is nice to have.

To understand wood lathe basics here’s a useful video to review:

Recommended 4 Lathes To Consider

I’ve ranked these lathes from small to large, so I’m sure there will be one in here to suit your needs. Let’s get started:

SHOP FOX W1704 1/3-Horsepower Benchtop Lathe

I like this little lathe. It’s a solid cast iron construction in a compact form. It’s ideal for small jobs such as turning pens or model making; powered by a 1/3 horsepower motor, it allows electronic speed adjustments from 700 rpm to 3,200 rpm. It’ll swing 8-inches over the bed and 12-inches between centers. My only concern is that, due to its size, it uses a #1 morse taper, which can make it hard to find a wide range of accessories.

That said, it comes with two tool rests to suit the different sizes of wood you may be turning and includes a faceplate. When turning bowls or other items that can’t use the tailstock as support, you’d use a faceplate.

I think the price of this model is great given that it’s of cast iron construction.

Pros

- Compact size

- Cast iron construction

- Good range of speeds

Cons

Morse taper #1 can limit finding aftermarket accessories

Here’s a video review of the Shop Fox 1704:

RIKON Power Tools 70-105 10″ x 18″ 1/2 hp Mini Lathe

Stepping up a little, here’s a model that gives you greater horsepower, a 10-inch swing over the bed, and 18-inches between centers. Again, this model has a cast iron bed that bolts to a bench, so a quality construction without vibration. The speed control on this lathe is through manually changing belts onto different sized pulleys, and you get five speeds.

You don’t get a faceplate with this model, but you do get a live center. This device fits into the tailstock quill and has bearings that enable the center to turn with the wood. The tool rest, a knock-out bar, and a spur center are also included, with some wrenches for adjustment.

Pros

- Cast iron

- Live center included

- Self ejecting tailstock

- #2 morse taper

Cons

- No faceplate provided

- Manual speed changes

The following video gives useful information on the RIKON 70-105:

Grizzly Industrial T25920-12″ x 18″ Variable-Speed Benchtop Wood Lathe

At first glance, this lathe may not seem too different from the previous benchtop one, but it is a step up. You get the same distance between centers but another 2-inches of swing over the bed. The motor uses 3/4 horsepower to drive that larger capacity.

The T25920 has a variable speed ranging between 650 and 3,800 rpm and a digital speed readout. The package includes a live center, spur center, a knock-out bar, and a small faceplate. At this price, if I were buying a lathe to get me started, this would be the one.

Pros

- Cast iron

- Live center included

- Faceplate included

- #2 morse taper

Cons

None really – this is a nice package

For more information, view Grizzly’s video on the T25920:

Grizzly Industrial G0766-22″ x 42″ Variable-Speed Freestanding Wood Lathe

Now we’re getting serious! If you’re upgrading from a benchtop model and you need a bit of power and size, here’s one to consider. The G0766 runs off single-phase power but uses a 3-phase motor through a variable speed control unit, providing more than enough torque. With a cast-iron stand and a cast-iron bed, this lathe is sturdy.

Swinging 22-inches and with 42-inches between centers, the headstock is adjustable anywhere along the bed, as is the tailstock. The spindle can be indexed in 10-degree increments.

Pros

- Robust and powerful

- Cast iron stand and bed

- Digital speed readout

- 100 to 3,200 rpm

- Live center

- Spur center

- 6-inch faceplate

- #2 morse taper

Cons

Not a budget price – although it’s a lot of lathe for the money.

Check out this great presentation by Darbin Orvar on her massive Grizzly G0766:

Summary

Remember the key points to consider when purchasing a lathe for the first time. Motor power, swing over the bed, the distance between centers, adjustable speeds, and sturdy construction. While there are many other secondary issues, these are the ones to put some thought into before you buy.

A word of caution. It’s tempting to buy just what you need now, but remember that a big lathe can readily turn small objects, whereas a small lathe will never turn big objects. If you feel that your turning needs may grow, consider buying a size larger than you think you’ll need, and you’ll stave off the frustration and expense of buying something that doesn’t grow with your needs.

I hope you found this article useful.