If you wish to make some shelving for your home and don’t know where to begin your wood selection, we’ll look at available options.

Although it’s important, shelves are not just about looks. In making shelves, you need to be aware of some basic structural issues in terms of the construction and understand the object sizes and weights you’ll be placing on the shelves.

Stay with us for the next few minutes, and we’ll discuss some wood options you might consider.

Natural versus Engineered Wood

The first choice to consider is whether to use natural planks or engineered wood. Engineered wood refers to sheets or planks made from thin veneers laminated together using glue, pressure, and heat. Examples include plywood, particleboard, medium-density fiberboard (MDF), laminate veneer (LVL), and cross-laminated veneer (CLT). Depending on your selection, engineered wood can provide structurally and cost advantages.

Choosing Engineered Wood

Of the examples mentioned above, I suggest plywood or particleboard as the most suitable choices. MDF is easy to cut and shape and looks great when assembled, but it’s soft and soaks up water like a sponge, puffing up and losing load-carrying capacity. LVL and CLT are both excellent products, and they look great, but unless you’re lucky enough to get an offcut, they’re mostly used in load-carrying beams in wide-span buildings and are well beyond most people’s budgets.

When using engineered wood, you will need to apply veneer strips on the edges of the cut sheets if you don’t wish to see the veneers or structure of the board. You can buy these strips from where you source your sheets and use glue to apply them.

Use a minimum thickness of 3/4-inch when using engineered wood for shelves; even thicker if the shelf carries large loads or spans larger distances. Both products discussed will sag if not thick enough or inadequately supported.

Plywood

Plywood comes as a sheet constructed by sandwiching thin wood veneers (or plies) of softwood or hardwood together with glue. When assembled for gluing, each veneer’s grain lies in a different direction of the veneers above and below. This assembly method creates a very dimensionally stable sheet that resists warping and bending.

When buying plywood, be aware there are different grades and classes. The grade refers to surface finish quality, and the class refers to the use to which the plywood is best suited.

Plywood Grades

We grade plywood surface finish by the letters A through D. As in an exam, A is the best and D is the worst:

A = a consistent appearance with little color variation and few if any tiny knots.

B = the appearance changes in color with a wood grain pattern evident and smooth knots to 1-1/2 inches.

C = discoloration, splits, and knots are apparent. Typically used in construction, not where appearance counts.

D = knots up to 2-1/2 inches with no repairs or filler.

The grade of a sheet will sometimes use two letters, one to denote the finish on the front face of the plywood sheet and the other to indicate the quality of the back face. So AB-Grade plywood is about the best you will see for surface finish.

Plywood Classes

Manufacturers class plywood according to where builders should use it. These classes are:

- Interior

- Exterior

- Marine, and

- Construction

While the names are self-explanatory, be aware that no plywood is 100% moisture-proof. All require protection; otherwise, the plies will separate, and the plywood will lose structural rigidity over time.

Particleboard

Constructed of chips of wood, glued and compressed into a sheet, particleboard is the timber most of us associate with the furniture you buy from places such as IKEA. It’s slightly cheaper than natural wood, and it can come with plastic or veneer faces for decorative effect. Be aware that particleboard does not suffer moisture well, so confine your use to indoor projects. As stated previously, you will need to glue a covering strip to exposed edges.

Particleboard is less forgiving of mistakes and doesn’t handle loads under tension, but it’s perfectly adequate when used as a countertop or a shelf carrying light loads. You will need sharp tools to cut it if it has a laminate face and beware breathing the dust when cutting as there’s lots of resin in that fine dust that you don’t need in your lungs. Please wear a mask.

Choosing Natural Wood

When choosing natural timber for your shelves, there are three practical considerations. The first is how resilient the timber is to knocks and scrapes; the second is price, and the third, appearance.

Janka Ratings

You may hear people speaking of the hardness rating of timber. This rating is called the Janka hardness, named after the person who developed the test. It measures how hard different timbers are by pressing a steel ball of known size into the wood to a depth of half the ball’s diameter. The pressure required to do this is measured, allowing one wood to be ranked against another for hardness. For more detail and some Janka ratings of different timber, here’s a link.

Pine is timber used often for jobs around the home. Yet, pine is very soft with a low Janka rating between 300 and 900. While pine shelves are easy to build and look great, they will wear badly, becoming dented and scraped very easily. On the other end of the scale, a timber often used for shelving is African Coralwood or Padauk. This timber is quite hard with a Janka rating of between 1,700 and 1,900. This timber resists knocks and scrapes and will maintain its look for longer.

With our recommendations below, we’ll advise the Janka rating to enable you to make some comparisons.

Price

It will be no surprise that the more exotic and rare the timber, the higher the price. This means that while mahogany shelves look marvelous and suggest quality and sophistication, it comes at a cost. Mahogany can be five to ten times more expensive than the cheaper timbers. We will indicate relative pricing; however, you owe it to your budget to investigate the cost before falling in love with a particular timber.

Appearance

Only you will know the look you intend. Pine or cedar may give a more country-style appearance, while oak and walnut suggest solidity or formality. In each suggested timber, we’ll try to give you a feel for the look to allow you to make the optimum suggestion.

Ten Suggested Natural Timbers for Shelves (Ranked by Hardness)

Pine

Janka Hardness: 400

Price: $

Used globally for timber and wood pulp. Farmed commercially. A resinous wood with little to no resistance to insects or rot. Best used indoors unless treated with an appropriate chemical preservative such as chromated copper arsenate. Takes stains and paints well, unless particularly resinous, in which case sanding and sealing is suggested before painting

With a defined grain and a color ranging from yellowish-white to reddish-brown, pine can have many knots throughout its structure. These knots can weaken planks, so careful selection is required.

Douglas Fir

Janka Hardness: 660

Price: $+

Light brown in color with hints of yellow and red, with darker growth rings, the grain of Douglas Fir is generally straight or slightly wavy. The texture is medium to coarse. While the wood resists decay, it is prone to insect attack. Paint, stains, or glues are well tolerated.

Dust can cause skin irritation, nausea, and giddiness.

Cedar

Janka Hardness: 900

Price: $$

A rich reddish-brown, cedar is naturally rot-resistant and therefore good for interior and exterior use. It comes in two types, white and red cedar. Both have a pleasant distinctive smell, with the white cedar weathering to a silvery grey, while the red becomes a lovely deep red. Cedar accepts stain and paints well, although finishes on white cedar prove to be more consistent.

Be aware that cedar produces natural oils, from which some people may become allergic. It’s best to avoid prolonged skin contact.

Cherry

Janka Hardness: 900 to 1,000

Price: $$+

Easy to work, with a fine texture, cherry has a beautiful pale color that ages to a rich reddish-brown. Resistant to insect and fungal attacks, cherry is moderately durable, depending on whether you have heartwood or sapwood. Not normally used for exterior applications, cherry can give blotchy finishes when stained. It’s best to use a sanding sealer before the stain is applied.

Some cherry sawdust can impact the respiratory system, causing wheezing. Dust masks are advised.

Walnut

Janka Hardness: 1,000 to 1,400

Price: $$$$

Light to dark chocolate brown, walnut has a fine, open grain with interesting patterns. When finished with a clear coating, walnut is exceptionally beautiful. The timber is described as moderately durable but with a low resistance to insects. To finish walnut, you need to put in a little more work than most timbers. Hand sand with the grain, getting progressively finer in grit. Blow or vacuum the surface, wet the wood to raise the grain, and lightly hand sand. When dry, apply shellac, and lightly sand again. Then apply stain, shellac, or oil as you wish.

Oak

Janka Hardness: 1,200

Price: $$+

Ranging from red to white with an attractive straight grain, timber from oak is hard-wearing with a coarse, uneven texture. Oak copes well with moisture and is rated as very durable and rot-resistant, and it takes stains, glue, and paint finishes well. A very strong and attractive timber.

Maple

Janka Hardness: 1,400

Price: $$

Hard maple is a dense and tough hardwood with tight, straight fine grain and a color that can range from cream through to gold. You can buy softer red maple also. It is not durable timber, prone to fungal and insect attacks, although fine for internal use.

Maple takes glue and paints well, but stains can be hit and miss. It is best to use either a gel stain or a pre-conditioner.

Hickory

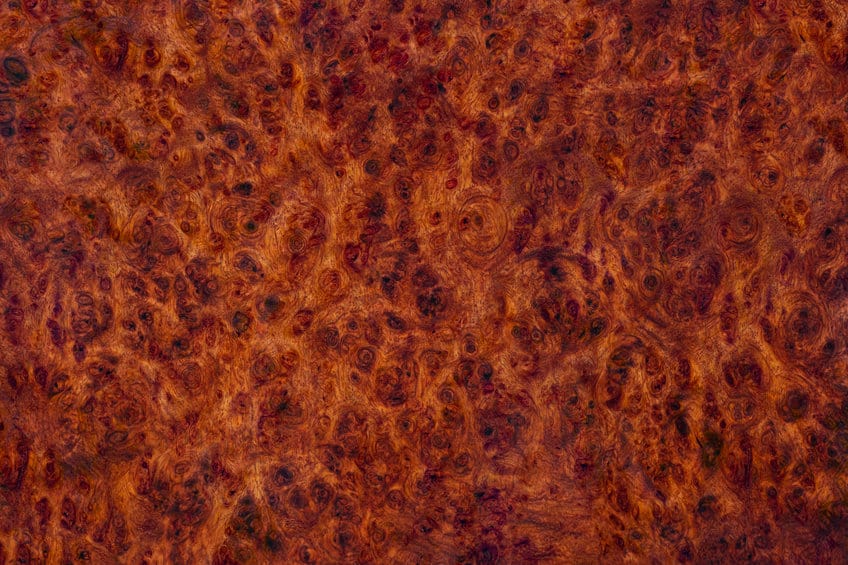

Solid American Hickory wood texture. Photo: 123rf.comJanka Hardness: 1,820

Price: $+

Light to medium brown with a slightly reddish hue, hickory is straight-grained, although sometimes wavy. The wood texture is medium with large open pores, and the wood is considered non-durable as it is susceptible to decay and insect attack. Hickory can be difficult to work if you don’t keep sharp edges on your tools, yet it does take stains, glues, and paint finishes well.

Goncalo Alves (Tigerwood)

Janka Hardness: 1,800 to 2,100

Price: $+

An irregularly colored wood, Goncalo Alves is usually reddish-brown with streaks of dark brown to black. Its grain is usually wavy, although sometimes straight, with a fine texture. The timber’s resistance to moisture makes it very durable while making it difficult to glue. The wood is stiff, strong, and hard, and Goncalo Alves finishes well.

African Coralwood (Padauk)

Janka Hardness: 1,970

Price: $$$+

A timber with lovely color ranging from pale orange to deep brownish-red, which darkens substantially over time. The grain is normally straight, with an open texture. Rated as durable to very durable, padauk is resistant to insects and has excellent decay resistance. It is easy to work, takes glue, and finishes well.