Knifemaking is an age-old craft, which has undergone a resurgence of interest in recent years. While much attention is paid to the blade design, the metal used, and sharpening methods, the handles are often a bit of an afterthought. However, I believe the handle adds usability, personality, and comfort to a knife.

Many materials are used for knife handles, such as metal, glass-reinforced plastics, carbon fiber, bone, and antler. Yet, to my mind, the material that best allows you to stamp your mark on a knife is the use of wood. Wood handles are warm, comfortable, soft on the hand, and attractive to look at. They’re also a sustainable resource that is biodegradable and renewable.

In this article, we’ll look at the best wood to consider for knife handles. We’ll also discuss some of the attributes you should consider when making your selection.

Hardwood or Softwood

You want your knife handles to resist damage, so your wood selection must concentrate on hardness or resilience. Let’s discuss the difference between hardwood and softwood. And no, one is not hard and the other soft. In fact, would it surprise you to know that balsa wood is a hardwood? Also, Yew is a softwood, but harder than many hardwoods!

Softwood comes from gymnosperm trees such as pine and spruce. Gymnosperm trees have needle-like leaves and bear their seeds in cones. Unlike many hardwoods, these trees are not deciduous, i.e., they do not lose their leaves in autumn.

Hardwoods come from angiosperm trees that have broad leaves and reproduce via flowers. Many are deciduous, losing their leaves in autumn when in temperate climates or during seasonal droughts in warmer climates.

Here’s a video that runs you through the differences described above:

So how do you select a hardwood suitable for knife handles?

Janka Rating

The Janka rating of wood is a ranking system for the wood’s hardness. It measures how hard different timbers are by pressing a steel ball of 0.444-inches diameter into the wood to a depth of half the ball’s diameter. The pressure required to do this is measured, allowing the ranking of one wood against another for hardness. For more detail and some Janka ratings of different timber, here’s a link.

Yet, remember there’s more to your selection than just hardness, as you want the wood to be aesthetically pleasing and reasonably easy to work.

Stabilized Wood

Some knife makers use stabilized wood to make their handles. Stabilizing wood protects and hardens it, preventing decay from humidity and moisture while dramatically improving wear resistance. The stabilization process immerses the wood in a penetrating resin, subjecting it first to vacuum, then releasing the vacuum to drive the resin into the wood capillaries. The resin bonds with and supports the cellulose in the wood, creating a linked plastic network throughout the timber structure.

For our detailed article on the stabilization process, follow this link, or this video takes you through the process step-by-step:

Eight Wood Types To Consider

Walnut

Janka Hardness: 1,000 to 1,400

Price: $$$$

Walnut has a fine, open grain with lovely patterns and colors ranging between light to dark chocolate brown. Described as moderately durable, walnut timber has a low resistance to insects. When finished with a clear coating, walnut is exceptionally beautiful. Yet, finishing walnut takes a little more work than most timbers. Hand sand with the grain, getting progressively finer in grit. Blow or vacuum the surface, wet the wood to raise the grain, and lightly hand sand. When dry, apply shellac, and lightly sand again. Then apply stain, shellac, or oil as you wish.

While walnut makes a lovely knife handle, it’s probably the least resistant to wear and knocks of the wood discussed today. Best for knives that see occasional use.

Oak

Janka Hardness: 1,200

Price: $$+

Oak has a wide color range, stretching from red to white, with an attractive straight grain. The timber from oak has a coarse, uneven texture which is hard-wearing. Oak copes well with moisture. Rated as very durable and rot-resistant, it takes glue, stains, and paint finishes well. A very strong and attractive timber, oak is easily shaped.

A highly regarded timber for making knife handles, oak is ideal for knives that receive heavy and prolonged use.

Cherry

Janka Hardness: 900 to 1,000

Price: $$+

Cherry is a wood that is easy to work with a fine texture. Its color when young is beautifully pale, which ages to a rich reddish-brown. Cherry is moderately durable, depending on whether you have heartwood or sapwood, and is resistant to insect and fungal attacks. However, cherry can give blotchy finishes when stained. It’s best to use a sanding sealer before the stain is applied.

It’s worthy of note that some cherry sawdust can impact the respiratory system, causing wheezing. Dust masks are advised.

Highly regarded for knife handles, cherry not only looks good, it’s durable and suitable for frequent use.

Hickory

Janka Hardness: 1,820

Price: $+

For years, hickory has been the gold standard for handles of all varieties, being straight-grained and shock-resistant. Light to medium brown, with a slightly reddish hue, the wood texture is medium with large open pores. It is considered non-durable as it is susceptible to decay and insect attack. Hickory can be difficult to work if you don’t keep sharp edges on your tools, yet it does take stains, glues, and paint finishes well.

Another highly-regarded timber for knife handles.

Cocobolo

Janka Hardness: 2,960

Price: $$$

Cocobolo comes from Central America and is highly prized for its wide range of colors and grain. Colors can range from yellow through orange, red, and brown, interspersed with streaks of black or purple. Cocobolo darkens with age. A naturally oily wood, cocobolo is resistant to rot and insect attack, being classed as very durable. Those natural oils pose difficulties when gluing, and if the surface is not sealed before finishing, the oil can cause the color to bleed into the surrounding wood.

Beware that the wood is known to be highly allergenic, causing eye, skin, and respiratory irritation as well as nausea. Those issues aside, the wood is highly regarded and used for musical instruments and fine furniture. Cocobolo is widely used for knife handles due to its durability, attractive colors, and grain.

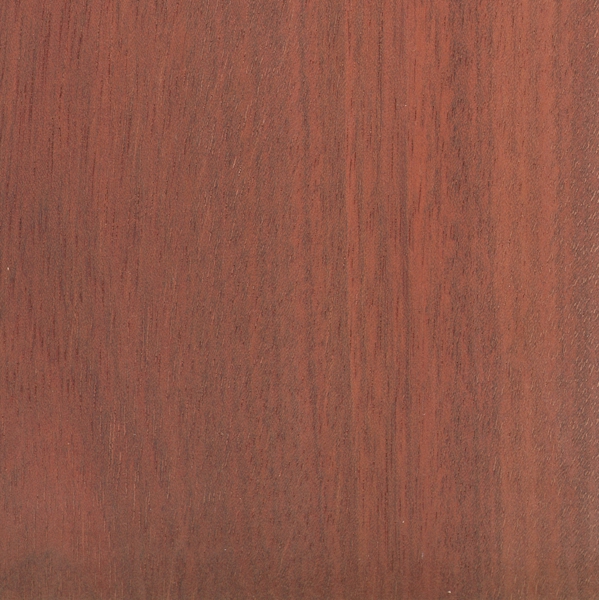

Bloodwood

Janka Hardness: 2,900

Price: $$+

Bloodwood comes from tropical South America. The tree’s heartwood has a vivid, bright red color that darkens to a brownish red on prolonged exposure to light. The grain is straight and fine, with a slight chatoyance or optical reflectance. Bloodwood is very durable and resists attacks from most insects. The wood is very dense, is brittle, and can splinter easily. These attributes make it difficult to work, blunting tools easily.

Highly prized for knife handles, musical instruments, and furniture, this wood’s durability, and color have made it extremely popular.

Indian Rosewood

Janka Hardness: 3,170

Price: $$$

Indian rosewood is extremely hard; look at that Janka rating. It has a lovely dark color, ranging from golden brown to a deep purplish-brown. Indian rosewood is another wood that darkens with age, becoming a deep brown. A dense timber with a narrowly interlocked grain, it has a medium texture and small pores.

It can be difficult to work, given its density, and it dulls cutting edges rapidly. While rosewood takes glues and finishes well, some of the resins in the wood can bleed onto surrounding surfaces when applying a finish, so be sure to use seal coats initially.

Indian rosewood is perfect for knife handles given its durability, making it ideal for knives that get tough everyday use.

African Blackwood

Janka Hardness: 3,670

Price: $$$$+

African Blackwood is often completely black with little discernible grain, hence the name, although the color can lighten to a purplish or dark brown hue. The grain is very fine and straight, with a good texture. Rated as very durable to decay, although not as durable to insects. This wood is very difficult to work on, and people often use metalworking tools given the extreme blunting effect on cutting edges. Considered the original ebony, African blackwood is among the hardest and densest woods you’ll find globally, exceeding even Lignum Vitae.

A highly prized timber for knife handles, African blackwood allows intricate carving and takes the punishment of everyday knife use.

Summary

While you have a wide variety of materials to choose from when making a knife handle, I consider wood the obvious choice. It’s eco-friendly, sustainable, biodegradable, warm, durable, and pleasing to look at.

If you’re looking for a small project, making yourself a knife is worth considering. Or perhaps you wish to rehandle an old faithful that’s showing its age. Today we’ve introduced eight kinds of wood you might consider using. To close, if you’d like to see the process of knife making from beginning to end, here’s a good video describing the application of a wooden handle: