Even if you’re an experienced woodworker, the different hand saws available, each with different names and uses, can be confusing. In this article, we’ll discuss the main saws you’re likely to encounter, describe the uses of each, and suggest examples you might consider purchasing.

Before we begin, it’s worth understanding that there are five main types of saw, based on their design. Within those types, there is a range of saws named for their application. Here’s a list of the types of saws we’ll discuss in this article:

- Hand Saws: Rip Saw, Crosscut Saw, Panel Saw, Pad Saw

- Back Saws: Carcase or Tenon Saw, Dovetail Saw

- Frame Saws: Fret Saw, Coping Saw, Junior Saw

- Specialty Saws: Nagokiri, Flush Saw, Veneer or Inlay Saw

- Forestry Saws: Pruning Saw, Bow Saw

Before We Start: Terminology

Parts of the Saw

A normal wood saw comprises two parts, the handle, and the blade. The blade has cutting teeth, which run along what is known as the front of the saw. The saw back is the smooth edge of the blade, which is the last bit of the blade to pass through the wood when cutting. The front of the blade closest to the handle is the heel, and the end furthest from the handle is the toe.

On a frame saw, the blade is simply that piece of metal holding the teeth, and the frame is the structure that holds and tensions the blade.

Teeth-Per-Inch (TPI)

The TPI count indicates how fine the saw cutting edge is by counting how many teeth there are in a 1-inch section of the blade. The finer the TPI, the smoother and slower the cut, and the thinner the material you can cut. Common TPI for rough-cut saws range from 1 to 7 TPI, medium-cut saws use 7 to 10 TPI, while finer-cut saws use 10 TPI or greater.

Hand Saws

Rip Saw

A rip saw is designed to cut wood parallel to the direction of the wood grain. The primary feature that supports ripping is the tooth design which has a flat front edge angled backward by around 8-degrees. Think of a row of small chisels facing forward in the direction of the cut. Such a tooth design prevents the blade from wandering as the cut progresses.

A rip saw is designed to cut on the push stroke and normally has between 4 and 8 TPI. They range in blade lengths from 22 to 27 inches.

Crosscut Saw

With teeth designed to cut at right-angles to the grain direction, they are angled at 15-degrees and sharpened like a knife to better sever the wood fibers. Cross-cut saws generally have a finer TPI than the rip saw, between 8 and 12 TPI, although, as with the rip saw, they are designed to cut on the push stroke. They can range in blade lengths from 23 to 27 inches.

Panel Saw

A panel saw is simply a saw with a shorter blade, usually 18 to 22 inches. Designed for portability and use on smaller pieces of wood. The TPI of a panel saw ranges between 8 to 12. Jobbing builders and carpenters often carry panel saws as they fit nicely into toolboxes.

Pad Saw

Known these days by various names, the pad saw or keyhole saw will often be called a jab saw or drywall saw. The purpose of the long thin pointed blade is to get into small areas or holes to cut shapes into wood. Ignore jab or drywall saws with huge aggressive teeth, as these are specially designed for plasterboard. We’re looking for thin tapering blades with approximately 10 to 12 TPI and straight or pistol grip handles. The blade can sometimes be removable from the handle.

Back Saws

So-called due to the strengthening spine that runs down the back of the saw. This spine stiffens the blade, allowing woodworkers better control while making accurate and fine cuts. These saws are used on fine work such as dovetails, tenons, or miter joints. Rather than the correct term of backsaw, the generic term used by many people for a backsaw is tenon saw, which tends to be confused with the real tenon saw.

Carcase Saw or Tenon Saw

The term carcase saw was used until the 20th century, after which the term tenon saw became more accepted. Of the two back saws, the carcase or tenon saw is the longest, at between 10 to 14 inches. It normally has the thickest blade of the back saw types and a TPI range between 10 to 14. Used for making straight and accurate cuts across the grain.

Dovetail Saw

The dovetail saw is a shorter and thinner backsaw than the carcase or tenon saw. No more than 10 inches long, with a TPI range between 14 and 20. While called the dovetail saw, carpenters extensively used it in the 18th century for fine cabinetry work. However, it is also good for creating dovetails due to its short length and thin blade, allowing precise control and accurate cuts along or with the grain.

Frame Saws

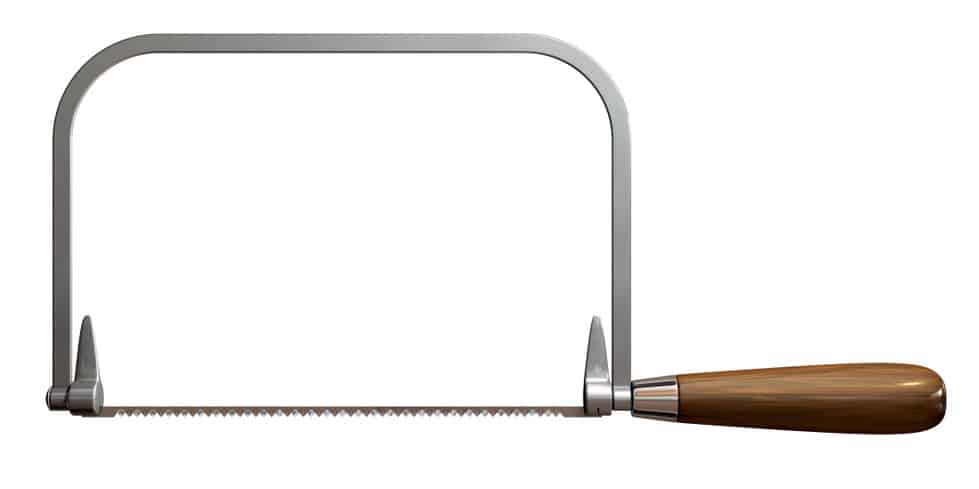

One look at a frame saw, and you understand where the name comes from. A-frame saw has a thin blade tensioned by a frame, made of wood or metal, with space between the frame and the blade. Frame saws are generally used for cutting curves, or when using a larger blade, they can also make straight cuts. The blade on some frame saws can be rotated 360 degrees to cut in any direction relative to the frame.

Fret Saw

A fret saw is used for intricate cuts that incorporate tight radii. The saw frame is very deep, while the blades are very shallow and thin, with a high TPI count, normally over 30. Blades can be the standard cut tooth blade we know from larger saws, or spiral cut wire, or wire impregnated with diamonds or carbide. They take their name from fretwork, that intricate geometric design that these saws are useful to create.

Coping Saw

Designed to cut internal or external shapes in woodwork and coped joints given the saws ability to cut fine lines and gentle curves. The coping saw is not as precise as the fret saw but sturdier with a shallower frame bow. The blade is inserted with the teeth pointing to the handle, cutting on the pull stroke.

Specialty Saws

Nokogiri, or Japanese Pull Saws

These saws cut on the pull stroke rather than the push stroke done by European saws. The teeth are razor-sharp, and the blade is very thin, allowing the user to make extremely accurate and clean cuts. I have some of these saws, and I love them. Very precise.

The photo above shows a Ryoba, a multi-purpose saw with two cutting edges, one side toothed for cross-cutting and the other for ripping. There is also a Dozuki, a single-edged saw with a rigid spine, similar to our back-saw. A kataba is also one-sided, coming in a rip or cross-cut version and used for flush cutting or with a saw guide. A mawashibiki is the equivalent of our keyhole saw.

Flush Saw

Flush saws are used to cut wood level with the face of another piece of timber without harming the face. Think of a dowel protruding through a plank. You need to cut the dowel flush with the plank’s face, so you reach for a flush saw. Teeth on a normal saw have a ‘set,’ where each tooth is bent or ‘set’ a few degrees to one side of the blade, and the next tooth bends to the other side by the same amount. This set creates a wider cut, or ‘kerf,’ which prevents the saw blade from jamming.

The teeth on a flush saw do not have a set but angle back toward the handle like small chisels. This feature allows the blade to ride on the face of a plank without marking it, cutting the dowel off at the same level as the face. You cut on the pull stroke.

Inlay, or Veneer Saw

As the name suggests, these peculiar-looking saws are designed to cut very thin sheets of wood, known as veneer. These saws are designed with an offset handle to get right up against a face and can be pull-to-cut, push-to-cut, or both, with 20 – 30 TPI on both sides of the blade. Used on a table with a straight edge to guide them, these saws require only light pressure and a few strokes to cut cleanly through the veneer.

Forestry Saws

Pruning Saw

Pruning saws are designed to cut through green tree branches, and therefore cleanliness of the cut is not such an issue. The emphasis is on cutting ease and speed, with teeth designed to cut in both directions, having between 5 to 12 TPI.

Bow Saw

A bow saw is a large version of our frame saws discussed earlier. With a large tubular frame doubling as the handle, the blade is tensioned between both ends of the frame. Similar to pruning saws, the teeth on bow saws are designed to cut on both the push and pull stroke.

The TPI depends on the wood to be cut. The blade usually has groups of three teeth for hard, dry timber, with a gap between each group. The TPI on this blade is normally 6 to 8.

When cutting green branches, the teeth are set in groups of four, with a raker tooth between each group. This raker tooth clears the chips made by the other teeth.

In Summary

In this article, we’ve discussed the different hand saws available, describing their uses and some details about them. We’ve also suggested an example of each saw we feel is a good introduction to that specific saw type to assist your buying decision. I hope you have found this article useful.